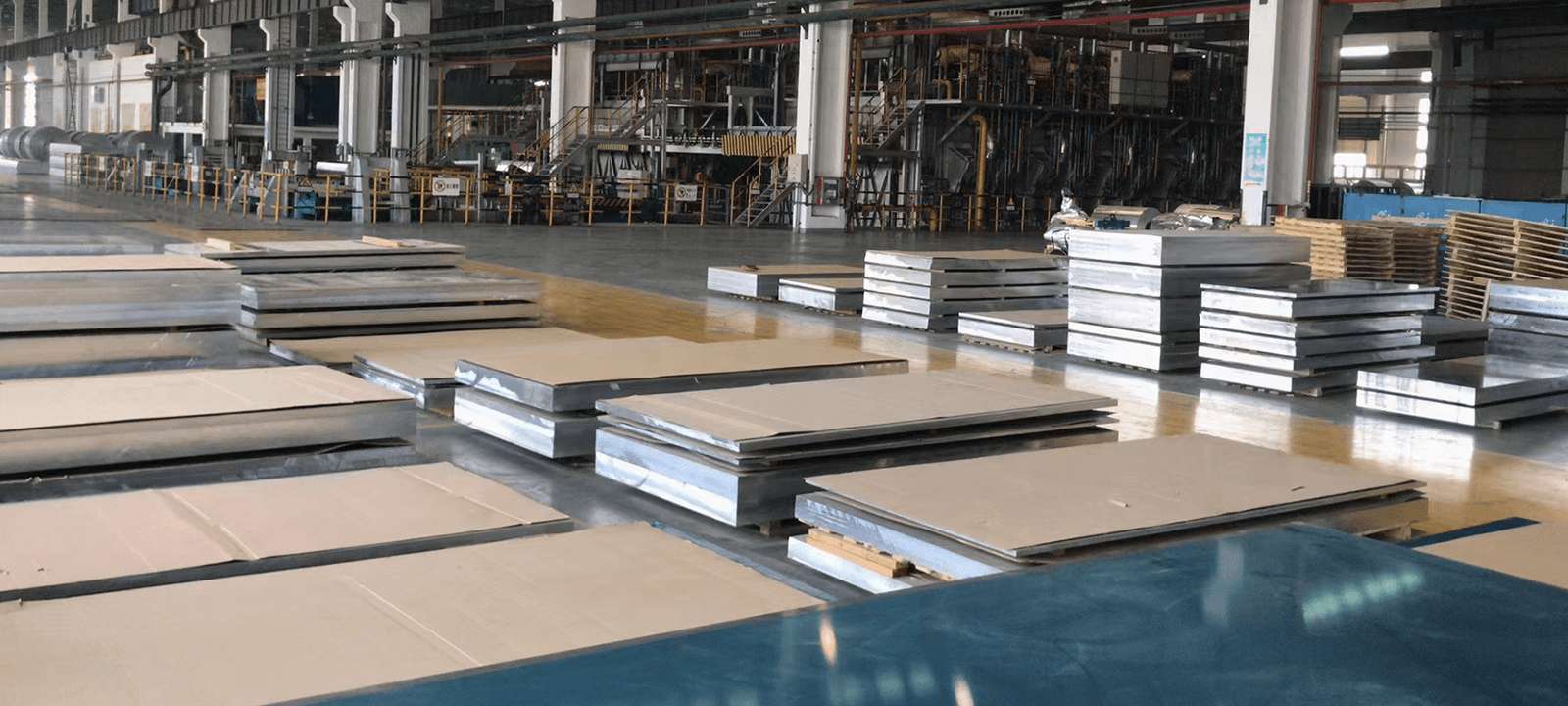

With the continuous development of global industrial economy, the demand in the market for pure aluminum or aluminum alloys has also increasing and diversified continuously. Aluminium sheets, also known as aluminium plates, Pure aluminum or aluminum alloy is the fastest changing and most widely used as the New Structural Metal Materials.

In fact, they are two different metals and both contain aluminum element. This article will be discussing here on the differences between aluminum sheet and aluminum alloy sheet.

Table of Contents

what is aluminum sheet?

what is aluminum alloy sheet?

Different Application

Side by Side Comparison – Aluminum sheet vs Aluminum Alloy sheet in Tabular Form

Summary – Aluminum sheet vs Aluminum Alloy sheet

What is Aluminum Sheet?

Aluminum is a silver-white and soft metal. It’s the atomic number 13 and the chemical symbo “Al”.

Generally speaking, aluminum sheet refers to pure aluminum sheet, which is made by aluminum ingots and pressed into a rectangle, the thickness is between 0.2MM-500MM.

When exposed to air, it can form an oxide film that prevents metal corrosion in a humid environment. However, because the film is extremely thin, its corrosion resistance is limited.

Some facts about pure aluminum sheet/plate are as below:

- Its chemical symbol: Al

- Its atmoic number:13

- Its density: 2.71g/cm3

- Its standard atomic weight: 26.98

- Its electron configuration: [Ne] 3s2 3p1

- Its form of the room temperature and pressure: solid

- Its melting point: 660.32 °C

- Its boiling point: 2470 °C

What is Aluminum Alloy Sheet?

Aluminum alloy sheet is a substance formed from mixing alumunum and one or more difference chemical elements such as magnesium, copper, chromium, silicon, zinc etc, which can enhance the properties of a metal.

According to the different alloy composition, it can be divided into:

- Pure aluminum sheet

- Alloy aluminum sheet (Aluminum as the main component, adding other elements such as magnesium, copper, chromium, silicon, zinc to aluminum)

- Clad aluminum sheet/composite aluminum plate (Made by a variety of materials, used for special purposes)

According to the thickness, it can be divided into:

- Thin sheet (thickness is 0.15mm-2.0mm),

- Starndard sheet (thickness is 2.0mm-6.0mm),

- Medium plate (thickness is 6.0mm-25.0mm),

- Thick plate (thickness is 25.0mm-200mm),

- Ultra-thick plate (thickness is above 200mm)

Aluminum alloy sheet or plates can be divided into 7 series,

- 1000 series mean that it is pure aluminium with a minimum 99% aluminium content such as 1060, 1050, 1070,1100 etc.

- 2000 series mean that aluminum is alloyed with copper, s Also known as “aviation aluminum alloy”. Because it is the expensive price for 2000 series aluminum alloy, few factories can directly produce it. At present, the 5052 series aluminum alloy is used to replace the 2000 series in civil use.

- 3000 series mean that aluminium is alloyed with manganese. Manganese content is usually between 2% and 5%. Its typical grades are 3003 aluminum plate and 3A21 aluminum plate. Because of its rust resistance, it is widely used in air conditioning and refrigerators. Compared with other alloy metal, its price has a great advantage.

- 4000 series mean that aluminum is alloyed with silicon, which is not widely used in the market.

- 5000 series mean that alumunium is alloyed with magnesium, which si very typical series. The main alloy grade is 5052, 5083 etc. It is the most commonly used aluminum alloy plate in the world

- 6000 series mean that aluminum is alloyed with magnesium and silicon, which are a combination of 4000 series and 5000 series. The typical alloy grade is 6063, 6061-T6.

- 7000 series mean that aliumium is alloyed with zinc, which has the has the characteristics of the highest hardness/ strengths. The grade is 7075.

- 8000 series mean that aliumium is alloyed with other elements. Its typical grade is 8011. It is mainly used to be make of bottle caps, but not commonly used elsewhere

Different Application

Each series of aluminum alloy plates has different uses.

For example, the 6 series aluminum alloy plate is an alloy plate represented by 6063-T5, which has a wide range of applications and good flexibility. It can be used to make various assembly line frames, workbenches, equipment covers, chassis cabinets, etc.

Due to the different composition of aluminum alloys, its density and strength are also different, and the characteristics of aluminum plates and aluminum alloy plates will also be different.

Aluminum sheets of different thicknesses are used in different fields. Thin sheets can be used for lighting appliances, household appliances such as refrigerators or microwave ovens, elevators, and automotive decorative parts; thick sheets can be used for aerospace aircraft, military supplies, ship decks, etc.

The below summary presents the differences between Aluminum Alloy sheet and Aluminum sheet for side by side comparison.