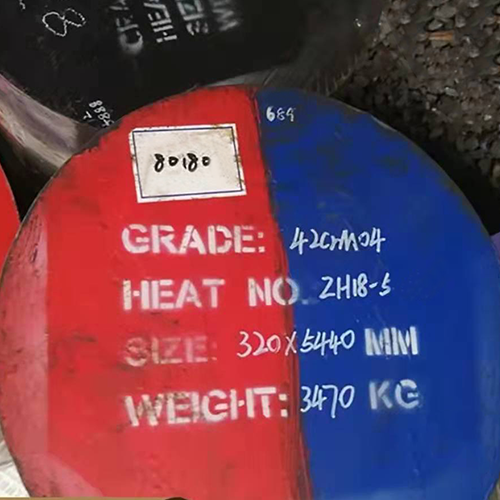

42CrMo4 | AISI 4140 | DIN 1.7225 | JIS SCM44 Alloy Engineering Steel

Description

42CrMo4 is structural steel and it’s very strong and hardenable. 42CrMo4 can achieve very good metal properties on the whole cross-section. For example, the maximum diameter is 70mm during quenching in oil and 50mm during quenching in water.

Furthermore, the overall performance of this heat-treated alloy steel is better than 35CrMo with using this kind of steel.

42CrMo4 steel is an improved steel grade of American AISI 4140 steel.

It is a good alternative for expensive chromium-nickel and chromium-nickel-molybdenum steel.

Composition

Table 1: Chemical composition ranges for 42CrMo4 Alloy Engineering Steel

| Grade | Standard | С | Cr | Mo | Mn | Si | P | S |

|---|---|---|---|---|---|---|---|---|

| 42CrMo4 (1.7225) | EN 10083-3 | 0.38-0.45 | 0.90-1.20 | 0.15-0.30 | 0.60-0.90 | 0.40 (Max) | 0.025 (Max) | 0.035 (Max) |

Possible Alternative

Table 2: Equivalent Alloy Material of 42CrMo4 Alloy Engineering Steel

| European | US | China | Japan | ISO | |||||

|---|---|---|---|---|---|---|---|---|---|

| Standard | Grade | Standard | Grade | Standard | Grade | Standard | Grade | Standard | Grade |

| EN 10083-3 | 42CrMo4 (1.7225) | AISI SAE; ASTM A29/A29M | 4140 | GB/T 3077 | 42CrMo | JISG 4105 | SCM440 | ISO 683-18 | 42CrMo4 |

Available Forms of 42CrMo4 in Market:

- Round bars

- Hexagonal Bars

- Flat bars

- Steel Tubes and Pipes

- Wires

- Steel Rods

- Forgings or Steel Die forgings

- Sheets and plates

- Cold-rolled steel strips