Corrosion is a natural occurrence and also has many different types of corrosion. Through corrosion, refined metals change into a more stable form like hydroxide, sulfide, or oxide. Corrosion destroys metals through reaction with their environment, either chemically or electrochemically.

There are two principal means of preventing corrosion; coating and cathodic protection. Cathodic protection suppresses the electrochemical reaction. But, the coating reduces the metals’ permeability and increases the wet adhesion. Other preventive measures include applying corrosion inhibitors, anodic inhibitors, metal design modification, scheduling regular maintenance, and keeping the metal surface dry also works.

Read on to understand more about corrosion and how to prevent corrosion in metals.

What Is Corrosion?

Corrosion is a chemical reaction. It distorts and tarnishes the structural integrity and appearance of metals. The reaction takes place when a metal reacts with an oxidizing agent from its environment.

Every type of metal has an individual electrochemical property. The electrochemical properties determine the kind of corrosion specific metals are vulnerable to. Iron tools are prone and susceptible to rust after long-term exposure to moisture. Copper tarnishes due to the effects of weather. Some metals resist corrosion more than others. However, no metal is free from all types of corrosion.

There are three primary necessities for corrosion to occur. Metal, an oxidizing agent that acts as the electron acceptor, and moisture. Rust is the most common form of corrosion. It appears as an orange-brown discoloration building upon the metal. Rust is quite unattractive. It affects any metallic objects exposed to moisture and oxygen.

What Causes Corrosion?

Once most of the atoms on the surface of the metal get oxidized, it is corroded. This is because of the damage caused to the entire body. Corrosion occurs as a result of interactions between unprotected metals with hydrogen, dirt, bacteria, or an electrical current.

The six common types of corrosion include; pitting, crevice, uniform, galvanic, intergranular and stress cracking corrosion.

How to Prevent Corrosion

There are different ways to prevent corrosion. They rely on the environment and on the metal itself.

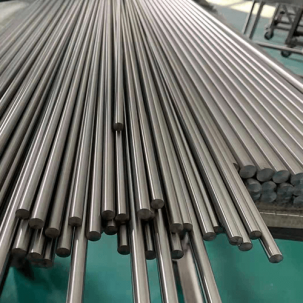

1. Using a Corrosion Resistant Metal

Using a corrosion-resistant metal is one of the simplest ways to prevent corrosion. Metals like stainless steel and aluminum are corrosion resistant. Such metals reduce the need for having additional corrosion protection. Other corrosion-resistant metals include galvanized steel, bronze, copper, and brass.

2. Applying Protective Coating

The coating creates a layer of protection on the metal. The coating acts as a barrier between the atmosphere’s oxidizing elements and the metal parts. Painting is one of the most common means of achieving that protective layer. Another common means of coating is galvanization. Galvanization involves coating the primary metal with a thin layer of zinc.

Another means of coating is the use of powder. Powder coating involves the application of powder on a clean metal then heating the metal. The process fuses the powder into a very smooth, unbroken film. A host of powder compositions can work in this process. Examples include; polyester, acrylic, urethane, nylon, and epoxy.

3. Taking Measures to Control Your Environment

Corrosion is due to a reaction between metals and gases in their surrounding environment. So, it’s possible to cut the reactions by controlling the environment. Minimization can be as simple as reducing the exposure of your metals to rain or seawater.

It helps store your metal parts inside a dry and clean place when you are not using them. If you intend to keep them in storage for a long time, consider controlling the oxidants’ level in the surrounding. Also, you should control the amount of chlorine, oxygen, or sulfur within the surrounding environment.

4. Control Corrosion Using Cathodic Protection

Cathodic protection takes place using a sacrificial anode. The process known as galvanizing involves attaching a reactive metal on the outer side of the metal you wish to protect. This method saves your metal at the expense of a smaller piece of metal.

For example, you can control the corrosion rate of mild steel by connecting it to zinc. Thus, Zinc becomes the sacrificial anode. While the steel is the cathode (thus cathodic protection). The zinc will then slowly corrode while the steel remains protected.

Cathodic protection is used in steel pipe products that ferry fuel or water, ship hulls, offshore oil platforms, and heater tanks.

5. Control Corrosion Using Anodic Protection

Anodic protection pertains to coating the metal you wish to protect with a less reactive metal. For instance, you can coat iron alloy steel with tin, which is less reactive. The container will not rust; therefore, the steel remains protected as long as the tin is in place. The name of the method is anodic because it makes steel the anode in an electrochemical cell.

Anodic protection is standard in carbon steel storage tanks that store caustic soda and sulphuric acid. The anodic means is more prevalent in storage tanks. This is because cathodic protection would fail due to the high current requirements.

6. Apply Corrosion Inhibitors

Corrosion inhibitors are chemical compounds that decrease the material’s corrosion rate if an alloy or metal contacts the fluid when added to a gas or liquid. Corrosive inhibitors also work by application on the metal surfaces. Inhibitors create a thin protective film to prevent oxidation.

The statue of liberty, for instance, has used a blue-green patina. The patina is a corrosion inhibitor, works to protect the copper underneath. Corrosion inhibitors are present in water treatment works, chemical production, and petroleum refining.

7. Consider Design Modification of Your Product

The design of metal plays a role in its rate of corrosion. Some design modifications could reduce corrosion. Other designs extend any preventive measure’s durability against corrosion that you had already done.

Metal designs should encourage free movement of air. The metal design should not trap water and dust; it should also avoid having any open crevices as they provide room for deposits.

8. Keep Your Metal Surface Clean and Dry

You must keep your metal surfaces clean and dry. Water is your number one enemy concerning corrosion. The oxygen in water molecules oxidizes your metal and corrodes it. The ability to remain dry is why metals that stay outdoors like tanks, gates, and cars have a high risk of rusting.

Any type of dirt adhered to your metal surfaces, such as mud, can hold water and lead to corrosion. You need to always clean up the surfaces. If you have an object located indoors but in a humid environment, consider installing a humidifier.

9. Schedule Regular Maintenance

Environmental control, cathodic protection, and proactive coatings, among others, are great ways to prevent corrosion of metal parts. But, such measures will not work if you fail to install consistent maintenance. Keep ongoing monitoring and maintenance. Over time, Coatings can start to wear. Even the smallest scratches and nicks could lead to corrosion.

Create a maintenance routine and do your check up on the state of the metal regularly. If you deal with huge metallic appliances, hiring a maintenance team is necessary. It’s as necessary as any other employee in your field. A blend of consistent maintenance and a suitable mode of preventing corrosion will have your metal lasting ages.

Why Prevention of Corrosion Is Necessary

Corrosion rates for different metals will vary according to their composition. The length of protection for your metal will depend on the individual metal itself. The longevity of the defense also depends on your choice of a preventive measure. The cost of preventing corrosion will also depend on the type of metal and protective means.

Irrespective of all the above variables, protecting metal from corrosion is important. You should practice any protective means when dealing with any metallic machinery.

1. Corrosion Is Harmful to The Environment

The environmental risk gets worse when the corroding metal is underwater or exposed to water. Allowing the corroded metal composition to mix with water could harm both plant and animal life.

Thus, it’s essential to take precautionary measures like anti-corrosive fluids and agents before releasing your metal. This ensures minimal harm to the environment.

2. Preventing Corrosion Saves You from Bigger Financial Losses

The corrosion of most metals leads to significant financial losses. Most metals are quite expensive, and replacing them is not cost-effective. Therefore, the breaking down of machines due to corrosion is an avoidable significant financial loss.

3. Avoiding Accidents

Corrosion can lead to the breaking down of a whole machine or mechanism. A sad example is the collapse of a bridge to prevent corrosion. Breaking down of machinery could lead to accidents, with some even life-threatening. With such extreme repercussions, prevention is better than cure.

4. Harmful to Human Health

Many of the chemicals produced during corrosion of various materials are harmful to human health, and a number can lead to diseases. Thus, it’s essential to nip the corrosion right in its bud and prevent its occurrence. Observing preventive measures for Corrosion not only saves the metal but also keeps human life free of harm or, even worse, death.

Final Thoughts

We often realize the risk corrosion poses in our daily lives. Corrosion could lead to severe accidents and loss of life for humans, animals, and even plants. The breaking down of weathered equipment on a plane or a rusty bridge, when left unattended, could take hundreds of lives and hurt. Life-sustaining industries, like the power and petroleum industry, could die if we do not prevent corrosion.

It’s also harmful to the environment and our economy. The world loses an estimated $2.5 trillion due to avoidable corrosion events. You may not save up from the protection of material from corrosion, but you will make some financial savings from repair and replacement costs. You also save the public’s health